Why do we need a new solution?

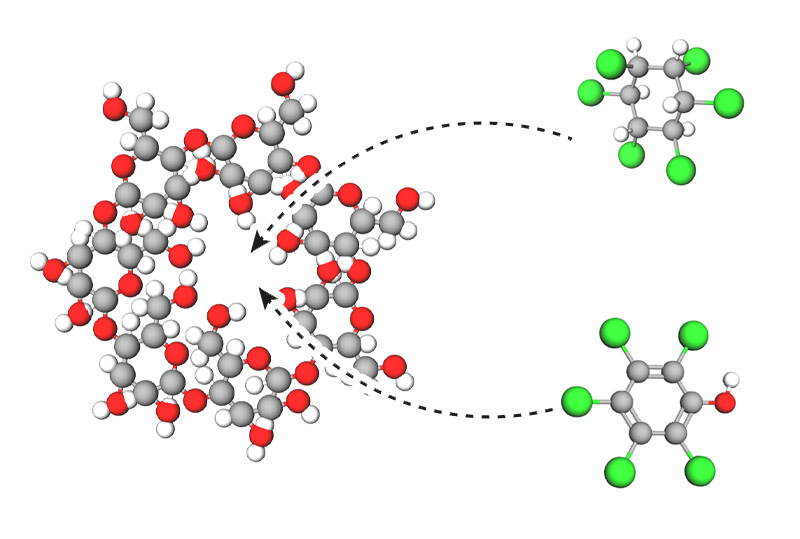

All through the 1970s and 1980s, wooden structures inside buildings were treated with wood preservatives containing pentachlorophenol (PCP) and lindane to guard against mold, rot and insects. Xyladecor and Xylamon, two commonly used products, are now known to contain carcinogenic neurotoxins. Approximately 3 million residential and larger buildings in Germany are potentially contaminated with these substances. To prevent or at least mitigate harms to the health of building users, the treated wood is disposed of as hazardous waste, the contaminated areas are enclosed or isolated, or the rate of air exchange in the affected spaces is increased. However, these methods are not a sustainable solution from a health, energy, or historical preservation perspective.