Why do we need this new technology?

Concrete is the most commonly used material worldwide. However, cement production generates carbon dioxide (approximately 700 kg of CO2 per metric ton of cement), and sand suitable for use as a raw material is in increasingly short supply. In some areas of the world, mafia-like structures are already forming, illegally extracting sand from coastlines and riverbeds. Each year, some 40 billion metric tons of sand and gravel are used to produce concrete. That’s enough sand to build a wall with a width and height of 27 meters, stretching around the entire Equator.

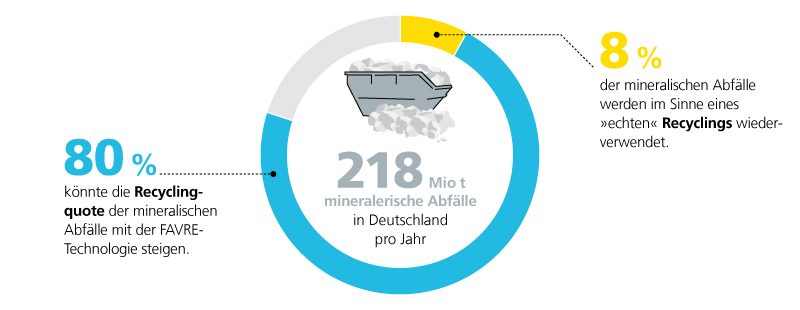

More than 218 million metric tons of inorganic waste was generated in Germany alone in 2018, according to Kreislaufwirtschaft Bau, an initiative working toward a circular economy in the construction sector. In principle, it should be possible to recycle the raw materials involved in this human activity. But so far, there has not been a suitable method for reclaiming sand and other raw materials for cement production from construction debris on a large scale. Just eight percent of this waste is currently recycled. Some 70 percent of waste concrete is used in roadbeds.

“But that’s not recycling, it’s downcycling,” says Dr. Volker Thome, head of the Inorganic Materials and Recycling department at the Fraunhofer Institute for Building Physics IBP. It would only be genuine recycling if the waste concrete were reused to produce not only aggregate but also raw materials for new cement production. “Even if we only reclaimed the high-quality aggregates from waste concrete, that alone would be enough to achieve something like a tenfold increase in the recycling rate, pushing it up to as much as 80 percent.”

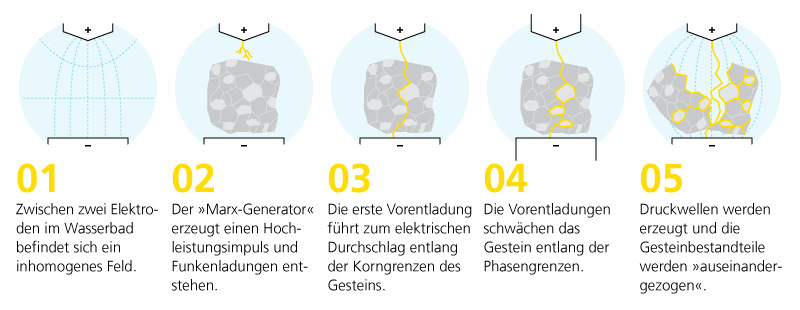

In the FAVRE project, Thome and his team are working on a new method of recycling construction debris for industrial application. The researchers have succeeded in using “ultra-short flashes” to break down waste concrete into its elements and process it so those fractions are available as substitute materials for production of cement, thereby helping to protect the climate and conserve resources.